Godhand

Godhand SPN-120 Ultimate Nipper 5.0

Couldn't load pickup availability

One of the best nippers for gunpla building in the market now. The ultra thin blade helps you to save more time while building your gunpla, and enjoy more.

The ultimate sharpness created by the ultimate ultra-thin blade!

The sharpness improves the finish and work efficiency!

Ultimate nippers are nippers that specialize in gate cutting and pursue the ultimate cut.

If you slice a runner of about Φ3mm, the blade will slip in and it will end with almost no sound.

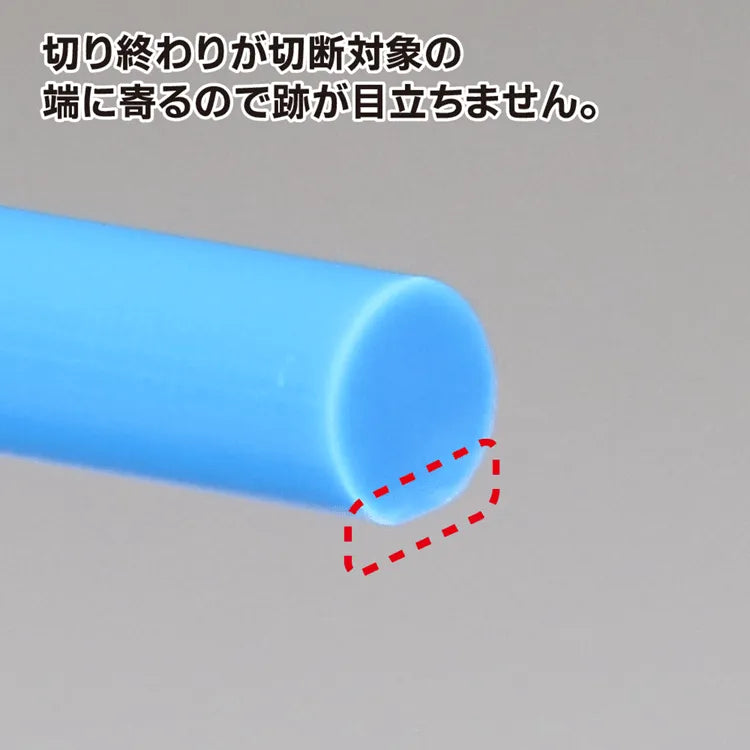

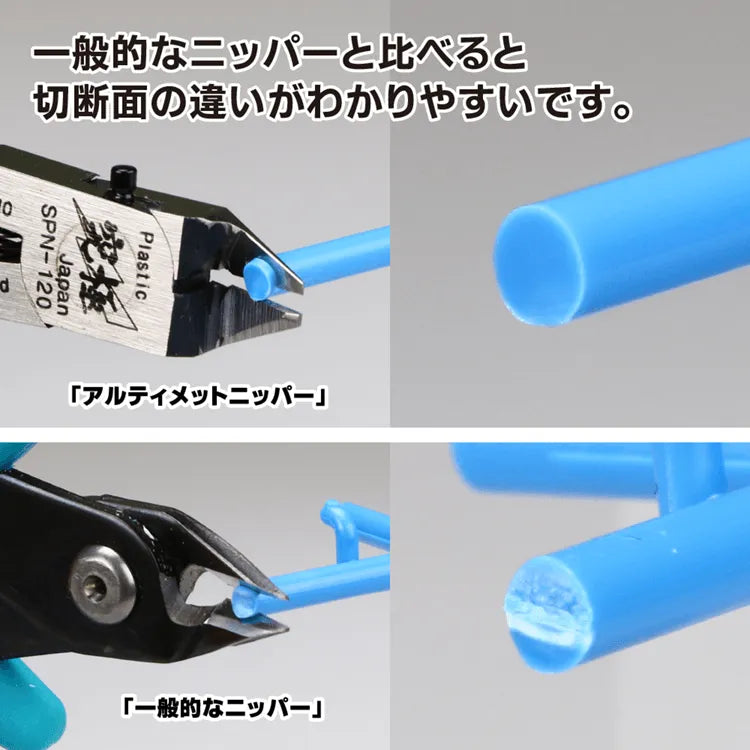

Because it is sharp, you can get a smooth cutting surface like shaved with a design knife, minimizing the whitening of plastic (the phenomenon that the cross-section becomes whitening).

Compared to general nippers, the cutting marks are much cleaner, so it is also recommended for those who want to complete the plastic model without painting.

Even for painters, even if you cut the blade along the part and cut it without leaving the gate, the cutting marks will not be removed, so the gate processing with a file or knife is minimal, and it can be used as a significant time-saving tool.

Even when cutting out small parts, the parts rarely fly away, and it is free from the trouble of searching for the flying parts.

The standard force for cutting Φ3mm plastic is 2 kg or less. ( The general nippers are 3.5 kg to 10 kg)

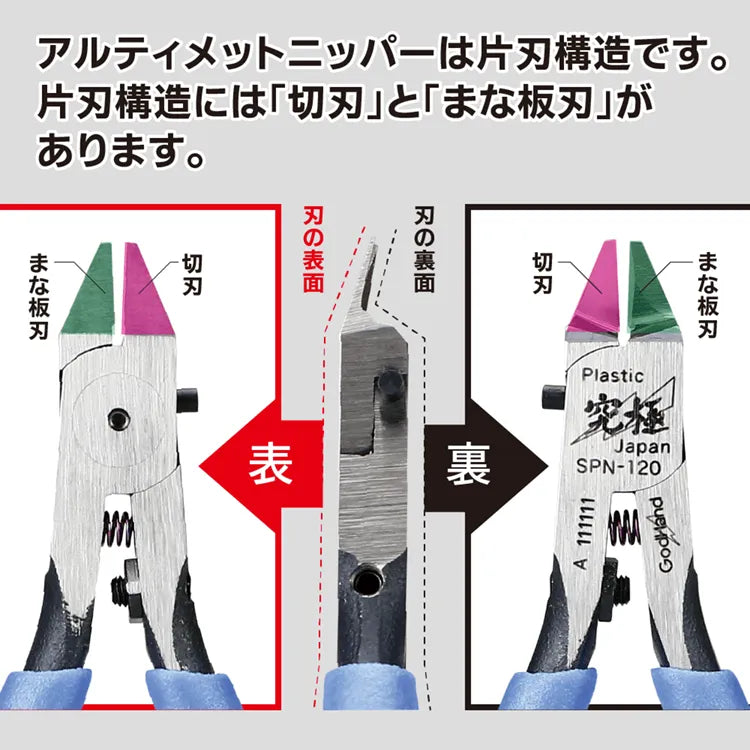

●"Cutting blade" and "single-blade structure" pursuing sharpness

What creates the amazing sharpness of the ultimate nipper is the thin and well-honed "cutting blade" and the "single-edged structure" for cutting more beautifully.

・Ultra-thin "cutting blade" by craftsmanship

A thin and sharp "cutting blade" that can be said to be the life of a ultimate nipper.

This "cutting blade" is created by the craftsmen of "Tsubame Sanjo" in Niigata Prefecture, which is famous for cutting edges, carefully attaching and sharpening the blade one by one.

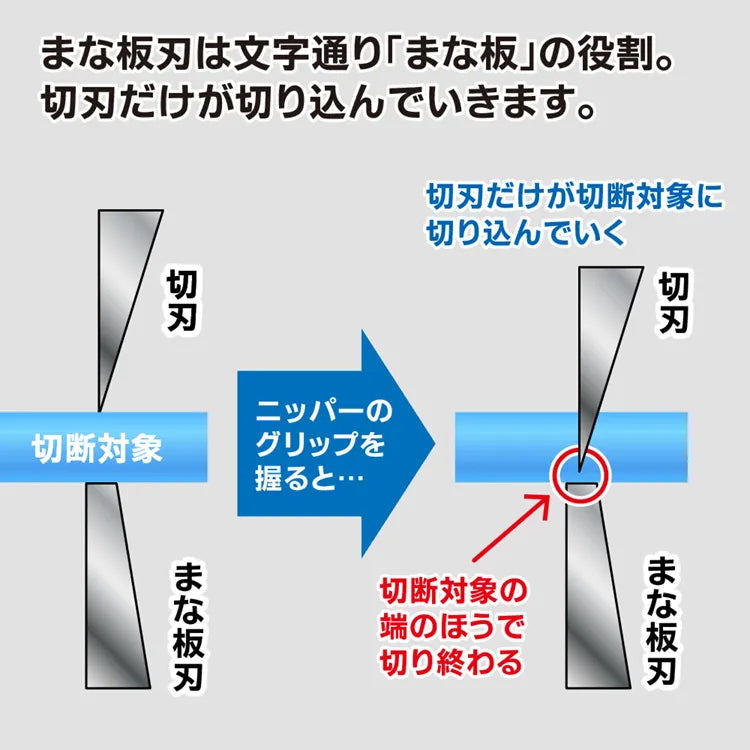

・"One-edged structure" for cutting cleanly

In order to obtain a clean cutting surface, the ultimate nipper adopts a "one-edged structure".

"One-edged structure" is a structure in which one of the blade is a "cutting blade" and the other is a "cutting blade". It is called "single blade" because there is only one blade (cutting blade) on one side.